How to Choose the Right Plastic Injection Mold for Your Project?

Choosing the right Plastic Injection Mold is crucial for the success of any manufacturing project. According to industry expert Dr. Samuel Brown, "The right mold can make or break your production efficiency." This statement highlights the significance of selecting the appropriate mold to meet your project requirements. A poorly chosen plastic injection mold can lead to reduced quality and increased costs.

Consider the specific needs of your project. Analyze the material, volume, and design intricacies involved. Each factor influences the type of mold needed. Not every mold will fit every project. For instance, a complex design may require a more advanced mold with additional features. It's essential to weigh the benefits and challenges associated with each option.

Mistakes can happen, even with careful planning. It’s easy to overlook crucial features or make assumptions about mold capabilities. Reflect on your previous experiences or consult with experts. Learning from past decisions can guide you toward better choices. Focusing on these details will ensure a more efficient manufacturing process and a successful outcome for your plastic injection mold project.

Understanding the Basics of Plastic Injection Molding

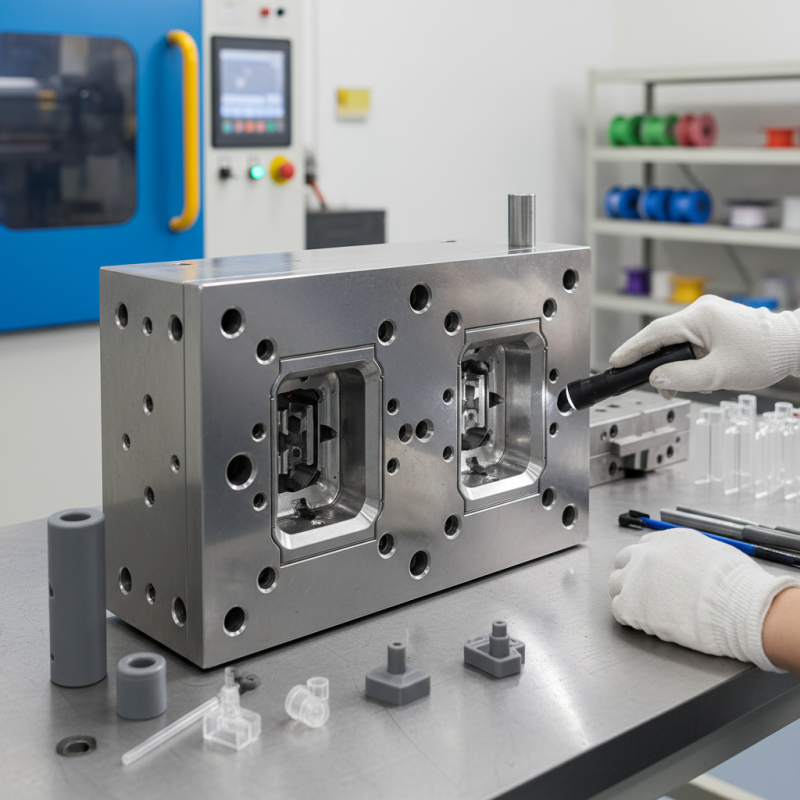

Plastic injection molding is a widely used manufacturing process. It involves injecting molten plastic into a mold cavity. Understanding its basics can help you become successful in your project. Each mold must be designed to meet specific requirements. The design needs to consider the type of plastic, part geometry, and production volume.

One key factor is the mold material. Steel and aluminum are common options. Steel is durable but more expensive. Aluminum is lightweight and requires shorter lead times. However, it may not last as long with high-volume production. Sometimes, the choice feels overwhelming. You must weigh the pros and cons of each option thoroughly.

Another aspect is mold complexity. Simple shapes are easier and cheaper to produce. Complex designs may require intricate details, which can increase costs. You should ask yourself if the added features are necessary. It’s often about balance—finding the right mix of cost and functionality. You may need to rethink your design to optimize the process.

Identifying Your Project Requirements and Specifications

Choosing the right plastic injection mold begins with a clear understanding of your project's requirements. You need to specify the part dimensions, tolerances, and material types. Each detail can significantly affect your mold design. A small overlooking in dimensions could lead to fitting issues later on. Consider the complexities of your part, as intricate designs may require specialized molds that cost more and take longer to produce.

Next, assess your production volume. Will it be a low or high run? High-volume production may require more durable molds. Think about the cooling systems too; they can enhance cycle times. If you are uncertain, consult with a mold specialist. They can often provide insights into design flaws you might have missed. Remember, a well-defined requirement often reduces costly mistakes. Adjustments later can add to your project timeline and budget. Balancing every aspect is crucial for a successful outcome.

Evaluating Different Mold Types and Their Applications

When evaluating different mold types for plastic injection, it’s crucial to understand their specific applications. For instance, thermoplastic molds are best for parts that require flexibility. This is a common choice for consumer products. However, thermosetting molds offer more durability. They are suitable for industries like automotive and aerospace.

Industry reports indicate that about 45% of manufacturers prefer multi-cavity molds due to their efficiency. These molds can produce multiple parts in a single cycle. Yet, they require more upfront investment. The decision may lead to challenges in balancing cost and production speed.

Another factor is the material used for the mold itself. Steel molds promise longevity and precision, making them ideal for large-scale manufacturing. In contrast, aluminum molds are lighter and cheaper but wear out faster. This trade-off can affect project timelines and costs. An analysis of your project’s specific needs is essential. Selecting the wrong type can result in increased downtime and unexpected expenses.

Comparison of Different Plastic Injection Mold Types

Choosing the Right Material for Your Injection Mold

Choosing the right material for your injection mold is crucial. Different materials can significantly impact the performance and lifespan of the mold. Steel and aluminum are popular choices. Steel is durable and ideal for high-volume production. However, it can be costly and take longer to machine. Aluminum, on the other hand, is lighter and easier to work with. It's best suited for low-volume projects.

Consider the project requirements carefully. If your parts need precise dimensions, a hard steel mold is often the best choice. For shorter runs, aluminum may suffice, but it may wear out faster. It's essential to balance cost and performance. Reflecting on your specific needs can lead to better material selection.

Quality is key, but it often comes with a price. Sometimes, choosing a cheaper material can lead to complications later. Keep this in mind during your selection process. Think about not just the upfront costs but the long-term implications too. The goal is to enhance efficiency and reduce waste. This might require re-evaluation and further investment.

Assessing Costs and Lead Times for Mold Production

When choosing a plastic injection mold, assessing costs and lead times is crucial. Production of molds can vary significantly based on complexity. A recent industry report indicated that the cost of a standard mold typically ranges from $5,000 to $100,000. However, intricate designs could push this figure even higher.

Lead times also fluctuate based on design intricacy and material choice. Simple molds may have a lead time of 4 to 6 weeks, while complex molds can take up to 12 weeks. This discrepancy can impact overall project timelines. Companies often need to balance speed and cost, which can lead to tough decisions. Rapid prototyping might seem attractive, but it doesn't always guarantee the best long-term solution.

Moreover, underestimating costs can be problematic. Hidden fees for alterations or emergency rush orders can arise unexpectedly. A mold that seems inexpensive upfront could end up costing more than anticipated. It’s essential to evaluate long-term goals and potential adjustments needed later. Attention to these factors will help ensure project success.